Microplastic Free and Energy Saving

In recent years the industry have become more aware of the effects that the use of microplastics in seed treatments have on the environment, the seeds, the plants and human health. It has even been identified as a global threat and in Europe the ECHA (European Chemical Agency) is preparing restrictions on seed coat liquids containing microplastics which is planned to go into force July 2021. On a yearly base this restriction will prevent, already only in Europe, 500.000 kilograms*1 of microplastics to be directly sown into our soils, contaminating our environment and threatening our wellbeing.

Effect of Microplastics on Germination

The biggest issue with microplastics is that these are not visible with the naked eye, even under a microscope microplastics can be hard to detect. Recent studies have shown us that these plastic particles can even enter into plant cells and by doing so reducing the growth of root length and biomass ratio*2. Furthermore, microplastics can create a physical blockage of the pores in the seed capsule resulting in damaged root and shoot growth. Also due to the accumulation of the microplastics close to the root hairs it inhibits the root hairs its imbibition of water and nutrients from the soil*3.

Why Biodegradable or Bio Based Polymers Will Not Tackle The Problem

Lately there has been a lot of talk about biodegradable polymers or bio based polymers to replace microplastics in seed treatments. In the new regulations it is stated that the time for biodegradability to hydrocarbon level is maximum 48 months (ECHA), most of these polymers do have a much longer biodegradability time (up to 200 years!). Therefore, using these types of bio polymers does not solve the problems that come with left behind fragments of seed coating after germination of the treated seeds. These fragments contain relatively high concentrations of to the seedcoat added treatment products such as insecticides. Because of the long biodegradability time of biodegradable or bio based polymers in the seed coatings, these fragments create spikes in e.g. left behind insecticide residues in the soil, which eventually get caught by the wind and so threatening biodiversity in soil and air*4. This is one of the reasons why our seed coat liquids are not based on microplastics, biodegradable or bio based polymers.

Microplastic Free Seed Treatments

Seedcoat liquids

Our seed coat liquids are based on a totally different approach and are not based on bio- or synthetic polymers. Our Film coat liquids consists of ingredients that are all 100% organic and 100% biodegradable within 12 months, this is well within the 48 months set as the maximum by the ECHA. Our approach enables the rheopectic behavior of our seed coat liquids, which means that the fluids solidify. This makes that our film coat liquids contain a very low content of free water (<1%). This enables the following benefits;

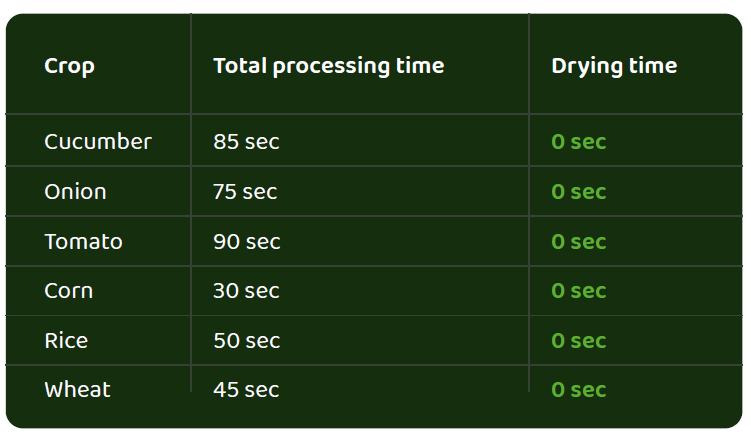

• No drying is needed after application

• Total processing time of max. 90 seconds per batch*

• Applicable on all seed types (vegetables, flowers, trees)

• Can also be used in organic farming

• Very economical in use

Pelleting, Encrusting Powders and Binders

Our Fixum binders and Circumeo pelleting and encrusting powders are all of course microplastic free and can also be used in organic farming. Our Fixum binders are fast drying in combination with our Circumeo powders. For example a batch of onion pellets (two million pellets) takes approximately 20 minutes to dry without using heated air, saving a lot of energy while creating a pellet with extreme low dust, good friability and homogenic hardness of the pellets. Also with encrusting using our Fixum binders in combination our Circumeo powders results in a fast drying process. For example a batch of 9 million seeds encrusted till 100% of the seeds weight takes approximately 3 minutes to dry, without heated air. These characteristics of our products result in homogenic and fast germination in the field.

Energy Saving

Next to the improved seed health, also a large amount of costly and precious energy can be saved by using our seed treatments. Firstly for the seed coatings, milling time or machining time is reduced significantly because of the extremely fast processing time and because drying after application is not needed anymore. Secondly, the drying process of pelleted and encrusted seeds is approximately four times faster when using our Circumeo Powders and Fixum binders. Because of these characteristics a lot of time and energy can be saved.

All our seed treatment products are designed in such a way that the seed industry will be ready for the future, which demands sustainable products of top-notch quality, so that food safety can be secured without contaminating the environment. For this reason all products produced by us are microplastic free and 100% organic, not because we are obliged to do so due to new regulations and laws, but because it’s better for the health of your precious products , the seeds, the crops that grow from the seeds, and for the condition of the environment wherein your seeds grow.

Microplastic Free, Naturally!

Do you want to know more? We are here to help you. Feel free to reach out via phone or e-mail and we will get back to you.

E-mail us at info@ad-terram.nl

Or give us a call at: (+31)228 593813

1. European Chemical Agency 2020, Opinion on the Annex XV dossier proposing restrictions on intentionally added microplastics. 2. Sander van Weert, Paula E. Redondo-Hasselerharm, Noël J. Diepens, Albert A. Koelmans, Effects of nanoplastics and

microplastics on the growth of sediment-rooted macrophytes, Science of The Total Environment, Volume 654, 2019, Wageningen University & Research 3. Y.S.K. De Silva1,2, U.M. Rajagopalan3 , H. Kadono1 2021, Microplastics on the growth of plants

and seed germination in aquatic and terrestrial ecosystems 4. Degradation of microplastic seed film-coating fragments in soil Cesare Accinelli a, * , Hamed K. Abbas b , W. Thomas Shier c , Alberto Vicari a , Nathan S. Little d , Maria Rosaria Aloise a ,

Sara Giacomini a a Department of Agricultural and Food Sciences, Alma Mater Studiorum – University of Bologna, Bologna, 40127, Italy b USDA-ARS, Biological Control of Pests Research Unit, Stoneville, MS, 38776, USA c Department of Medicinal

Chemistry, College of Pharmacy, University of Minnesota, Minneapolis, MN, 55455, USA d USDA-ARS, Southern Insect Management Research Unit, Stoneville, MS, 38776, USA)